Handling Procedure

The process to deal with customer Complaints

- Listen to the complaint. Thank the customer for bringing the matter to your attention.

- Record details of the complaint.

- Get all the facts.

- Discuss options for fixing the problem.

- Act quickly.

- Keep your promises.

- Follow up.

Installation of Optical fibre Cable by Blowing / Jetting

Optical fibre cables for telecommunication applications have been installed in pipes/ducts for many years. The installation process is influenced by local conditions, local climate, customer's existing procedures, and customer requirements. There are two basic methods of cable installation in a preinstalled duct - pulling method and blowing method. The cable installation method is selected based on site conditions and the availability of machinery & resources. Table 1 shows a comparison between the two installation methods.

Comparison between Pulling and Blowing methods

Pulling methods

- Pulling rope pre-installed

- Equipment and manpower on two sides

- High sidewall forces on cables and ducts may lead to cable damage

- Mainly manual pulling is practiced. Machine pulling needs one hydraulic power pack

- Mainly used for straight duct route

- Suitable for short-distance (few '100 meters) installations.

Blowing methods

- No pulling rope to install

- Equipment and manpower on one side

- Forces on cable and duct can be monitored and controlled and minimal chance of cable damage

- Large compressor and/or hydraulic power pack at one side

- Preferred for duct route with multiple bends and undulations

- Preferred for long-distance (over 2 km) installation

Overall, the blowing method is preferred over the traditional pulling method due to savings in manpower & installation time and improved installation efficiency, particularly in longer ducts with multiple bends and undulations. In this application note, cable installation by blowing method and its best practices are explained.

Pulling methods

Cable installation by using high-speed air flow combined with additional mechanical pushing force is called as "blowing or jetting". Cable blowing is the process of installation of optical fibre cable into a pre-installed duct. Compressed air is injected into the duct inlet after a few hundred meters of cable is pushed into the duct. Compressed air flows at high speed through the duct and along the cable. The pushing force is applied mainly near the cable inlet by a pushing device. Standard optical fibre cables (like uni-tube, multi-tube, unarmoured & armoured ), microduct cables, and micro-ducts can be installed by using this method. It is possible to install microduct cable using the blowing method in continuous lengths of more than '1000 meters depending upon the duct route. There are two methods for blowing which are discussed below.

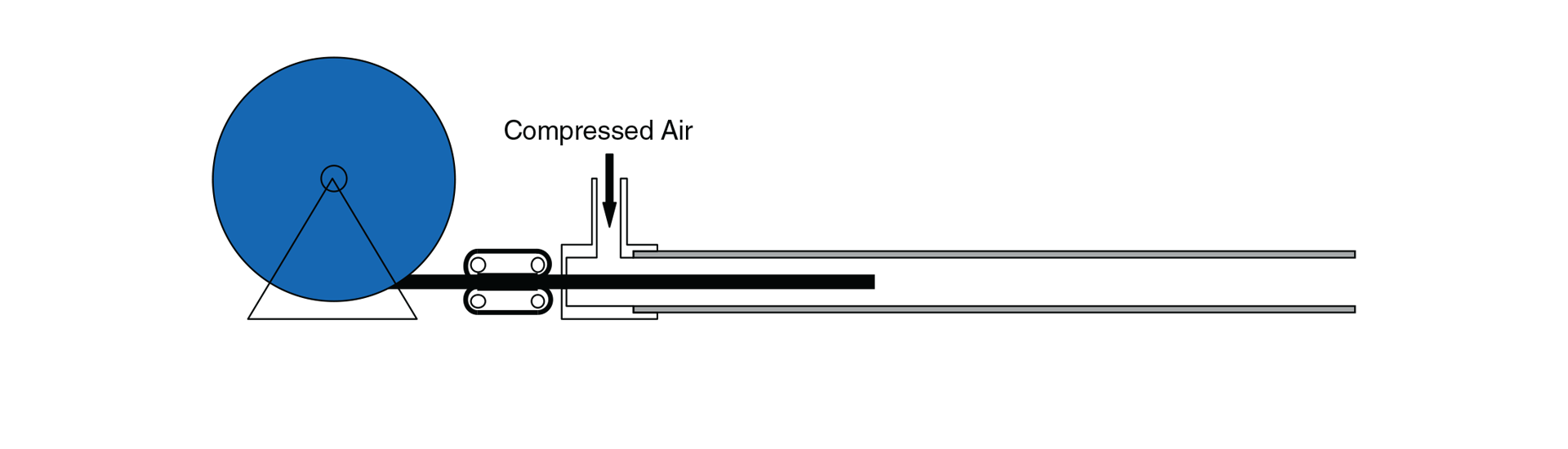

Method 1: High air speed blowing

This method requires pushing the cable with a tractor mechanism by traction rollers in a blowing

device for a few hundred meters and then introducing compressed air to make the cable inside the

ducts remain in floating condition, which reduces friction between the cable outer surface and

duct inner wall by reducing the area of contact as shown below in Figures '1 and 2.

Figure: 1

Figure: 2

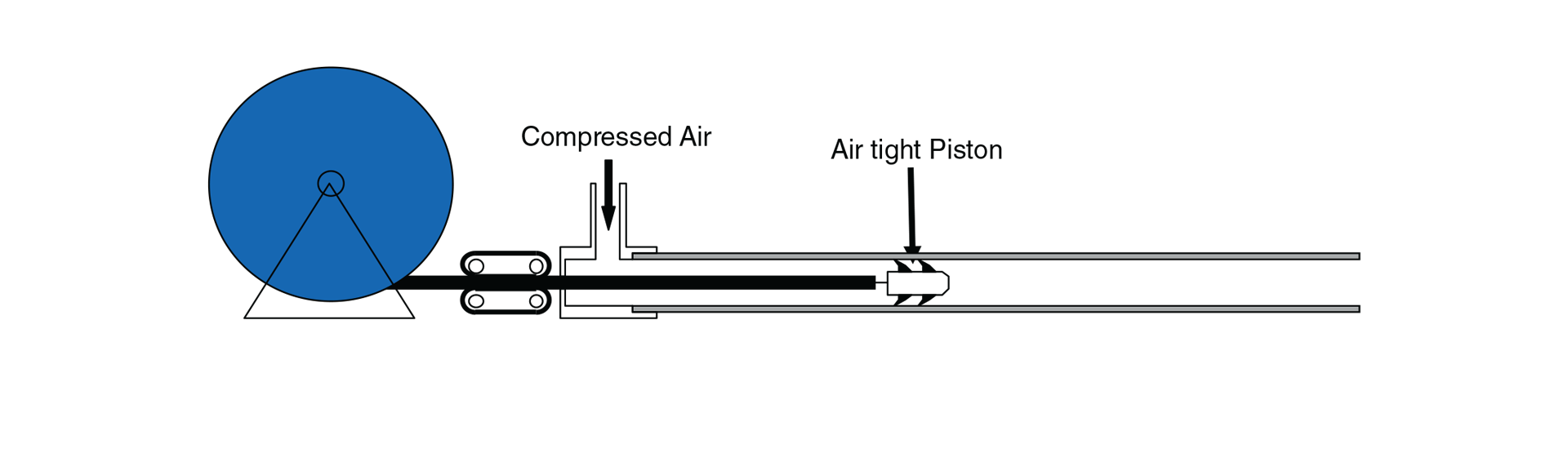

Method 2: Push/Pull (Piston) blowing

In this type of blowing unit, an air-tight piston is attached to the front of the cable. The air

pushes this piston, and the piston "pulls" the cable as shown in Figure 3. Installers should be

aware that a pulling force exists in piston blowing, and the pulling force shouldn't cross the

maximum cable tension. This method is preferred for larger size ducts (32140mm and 42150mm) and

in "straight" trajectories to achieve longer cable blowing distance.

Figure: 3

Key Parameters of Blowing Method

The following three major parameters and their combined effects control how far a cable can be

blown in a duct.

- Duct Fill Ratio (cable to duct size ratio)

- Coefficient of Friction (between cable outer surface and duct inner wall)

- Cable Stiffness (related to cable flexibility & undulations in duct route)

Duct Fill Ratio (DFR)

The ratio between cable and duct size is known as the 'Duct Fill Ratio' or 'Fill Ratio'. There

are

two methods to calculate DFR.

a) The ratio between cross- sectional area of the cable and the inner space of the duct.

b) The ratio between cable diameter and duct inner diameter.

For optimum blowing performance DFR to be kept between 30 to 80%.

For conventional cable of diameter ≥ 10 mm: 30 to 50%

For micro cable of diameter 1-9 mm: 30 to 80%

Higher DFR helps to achieve longer blowing distance particularly in straight route. Higher DFR

also prevents cable buckling effect (cable forming a helix inside the duct) particularly for

cables with low stiffness. However, high DFR may result in shorter blowing distance in the route

having multiple bends. Therefore, an optimized DFR needs to be maintained to achieve the best

blowing

performance.

Coefficient of Friction (CoF)

Coefficient of Friction can be termed as the drag force (sliding friction) generated during

cable blowing due to area of contact between cable and duct inner wall because of the mass of

the

cable and gravity. CoF mainly depends on elevation, bending in duct route, undulations in duct

and properties of cable outer jacket materials. Generally stiffer materials like Polymide, high-

density polyethylene (HOPE) give better blowing results as compared to low density polyethylene

(LOPE) and flame retardant material like low smoke zero halogens (LSZH). CoF can be reduced by

using lubricants during the blowing of the cable. Blowing with lubricants increases efficiency

approximately by 50 %. CoF is also influenced by the quality of ducts i.e. inner wall material

of

duct (smooth & ribbed). Generally blowing distance in ribbed inner wall duct will be more as

compared to the smooth inner wall due to less area of contact between cable outer surface & duct

inner wall. Various factors that influence CoF, are summarized in Table 2.

| Component | Important Parameters/Characteristics | How to reduce CoF |

|---|---|---|

| Cable | Weight, Stiffness, Construction | Use of materials with low stiffness |

| Duct | Material of construction and design | Quality of duct (use of virgin HOPE materials), Inner surface (smooth/ ribbed), Low friction lining, Pre-lubrication |

| Duct Route | Straightness, Number of bends, Bend radii, Elevations, Cleanliness | Straight laying of ducts, no deformations and/or kinks and maintain minimum bend diameter >30 x Outer cable diameter (or as specified in cable design sheet) |

| Blowing Equipment | Temperature of compressed air, Presence of moisture in compressed air | Use of after cooler and water separator in a warm and humid climate |

| Lubricant | Quality and Quantity of lubricants, Method of application of lubricants | The lubricant material should not react with cable outer sheath ( don't use soap water, kerosene, diesel), Apply the right quantity by sponge or lubricator as suggested by the supplier |

Cable Stiffness or flexibility

The stiffness or flexibility of cable also plays an important role in blowing performance.

Stiffness

depends on cable design construction i.e. metallic or non-metallic, central tube or multi-tube,

outer jacket material, etc. Stiffer cable can achieve more blowing distance in straight

trajectory and flexible cable can achieve more blowing distance in difficult trajectories or

routes

with multiple bends and grading. Stiffer cable is preferable as it can blow fast through

undulation in ducts and avoids buckling of cable inside the ducts.

Cable Blowing Best Practices

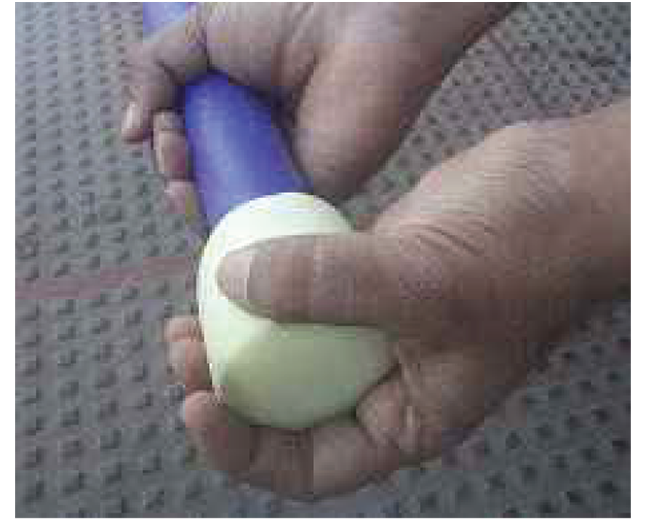

a) Cable Crash Test

Prior to cable blowing it is important to perform the crash test to determine the maximum

pushing

force that can be applied on cable. Higher pushing force by tractor mechanism can damage cable

outer sheath and cable buckling at entry point. This test involves pushing the cable from the

blowing

head into 5 to 10 meters of a duct that is sealed at the other end. When the cable stops after

hitting the sealed end of the duct then the blowing head must stop pushing the cable such that

there

is no damage to the cable outer jacket and no cable buckling at the entry point. This process is

repeated with an increase

in push force until cable jacket damage is witnessed. The maximum permissible push force will be

the highest push force without any damage to the cable jacket. This test ensures that the

tractor will not damage the cable during installation in case of sudden stoppage of blowing.

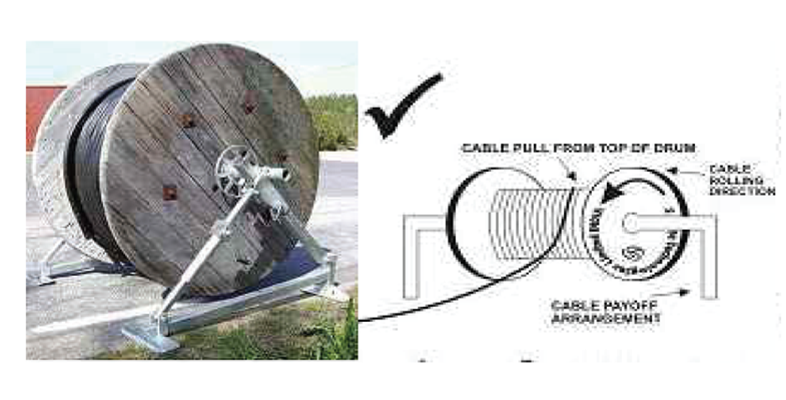

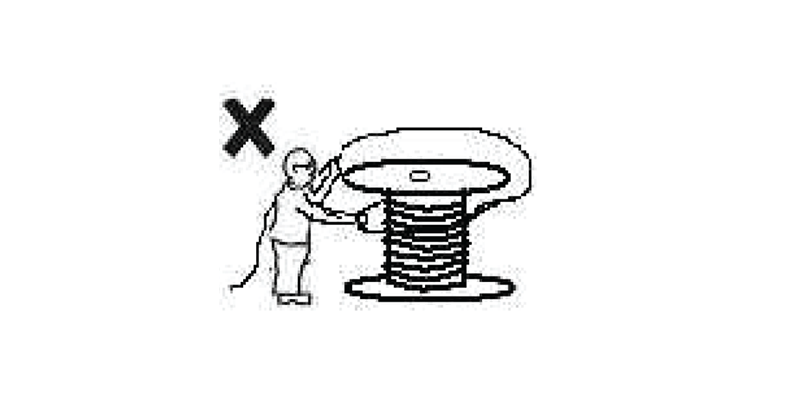

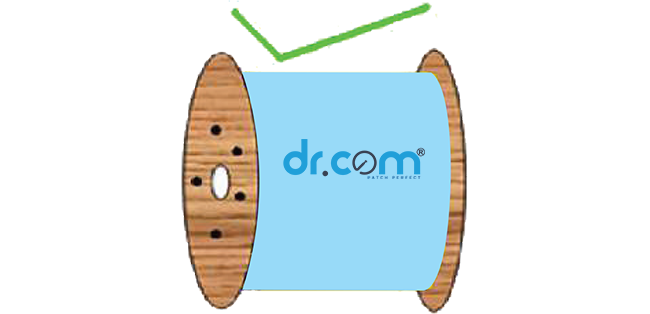

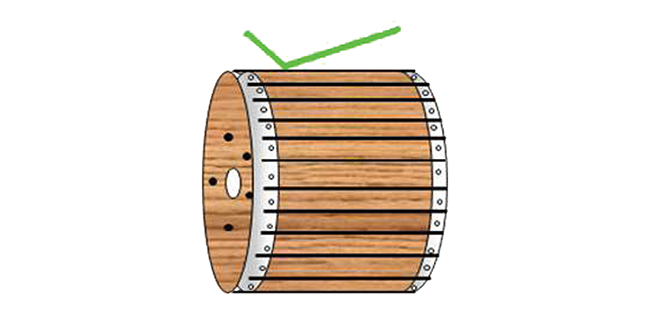

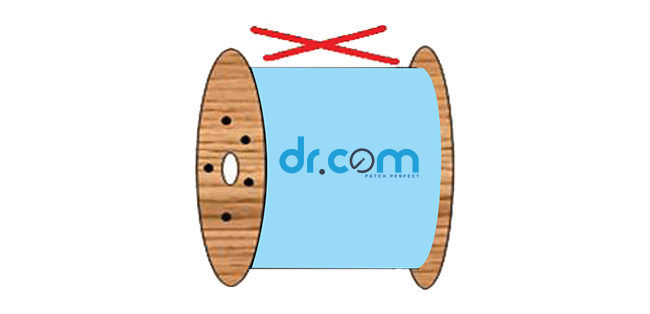

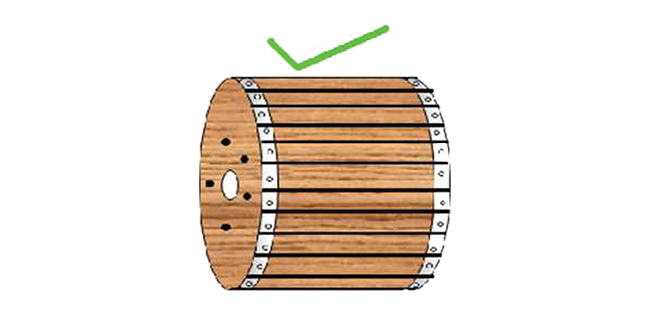

b) Cable drum pay-off

This feature is very important in a blowing setup to ensure the cable is smoothly pushed inside

the

duct through the blowing unit. It is always recommended to use cable reel pay-off during cable

installation. The cable drum should be kept level to avoid the cable rubbing against the drum

flanges. The cable drum orientation should be such that the natural payoff direction is towards

the pulling direction. To eliminate possible cable contact with the ground, cable payout should

be from the top of the drum. Figure 4 shows a cable drum in a cable drum pay-off and figure 5

shows the do's and don'ts of cable unwinding.

Figure: 4

Figure: 5

Duct Integrity Test (DIT)

The purpose of DIT is to prove that the installed ducts are ready to use for blowing from one

manhole

to the other. DIT should be performed before blowing to avoid sudden surprises like missing

sections

of ducts, improper coupling, and kink and blockage in ducts. The DIT is carried out with the

help of compressed air and a suitable go-gauge sponge and mandrel of appropriate size, which is

pushed inside from one end with pneumatic pressure and is thrown outside from the other end. The

three steps outlined below should be performed to conduct integrity.

a) Step 1: Air pressure test

Duct continuity is verified by introducing compressed air from one end of the duct, and checking

if

air comes out from the other end of the duct. If no air emerges then the fault point has to be

identified

and corrected before proceeding further. Duct leakage is verified with compressed air by

attaching

the compressed air unit head to one end of the duct, and attaching the pressure gauge to the

other

end of the duct. Compressed air at a pressure of 10 bar is applied at the first end for 10 - 15

minutes

and air pressure drop at the other end of the duct is measured. If the pressure reading remains

the

same (not reduced to zero) at other ends for 5-10 minutes then there is no leakage in the duct.

If

the pressure reading drops to zero then there is leakage in the coupler (that joins two ducts),

and

the duct is punctured. Figure 6 shows a pressure gauge fixed at one end of the duct to monitor

air

pressure.

Figure: 6

c) Step 2: Shuttle test The kink in the installed ducts is located by shuttle test. A suitable shuttle of size 70-80% of the duct inner diameter is passed through the duct with the help of compressed air. If the shuttle comes out from the other end then the duct has no blockage and it is considered ready for cable blowing. If the shuttle does not come from the other end, then the duct is either kinked or blocked. To identify the blockage or kinked location, a transmitter is passed through the duct which will get stuck behind the shuttle and then the blockage point in the duct is tracked with the help of the receiver. The blocked portion of the duct is dug out and replaced. Figures 7 and 8 show a shuttle being inserted in a duct.

Figure: 7

Figure: 8

d) Step 3: Sponge Test Very often mud and water are found inside an underground duct. In this test, a sponge double the size of the duct inner diameter is passed through by compressed air to clean the duct. Figures 9 and 10 show a sponge being inserted into a duct.

Figure: 9

Figure: 10

A metal cap is fixed at the head of cable as shown in figure 11, to seal the cable end so that jelly or other elements of the cable will not damage the duct inner wall and cable blowing will be smooth.

Figure: 11

Handling of Rejected Material

PURPOSE

To lay down the procedure for handling of rejected material.

SCOPE

This procedure is applicable in Quality Assurance, Quality Control, Production, and Warehouse.

RESPONSIBILITY

- Manager - Quality Control

- Manager - Production

- Manager - Warehouse

ACCOUNTABILITY

- Manager - Quality Assurance

PROCEDURE

Rejected material shall be segregated to

keep it in its designated place with rejected status.

a. Rejected raw/packaging material shall be kept in a Rejected area of the warehouse.

b. Online rejected material (Raw/Packaging materials, intermediates, semifinished and

finished product) shall be transferred to Warehouse with on line rejection note (OLRN) and

Warehouse shall keep in the rejected area. Attach a copy of OLRN along with the respective

batch.

c. Warehouse / Production shall be informed to QA about the rejection through Rejection

Intimation Note

d. QA shall verify the type of rejected material, reason for rejection, investigation and

its results.

e. On verification QA shall decide for further disposal as follows.

f. Return to vendor in case of Raw/packaging material (Other than printed packaging

material).

g. Reprocessing / Rework of intermediate, semi-finished or finished goods.

h. Destruction of material.

i. QA shall document its decision of disposal and ensure the disposal happens.

j. All rejected printed packaging material shall not be returned to the vendor and are

destructed on site.

k. Destruction shall be recorded in Material Destruction Record

Safety Procedure

This document provides the guidelines for handling, transportation, and storage

of

Optical fibre cable drums. These guidelines can apply to all 'Outside Plant Optical fibre

Cables'. This document provides information for the handling various reels/drums at various

places from receiving in stores to shipment to the site for installation.

Proper handling of cable reels/drums decreases the probability of accidental damage to cable,

material & personnel. All-optical fibre cables are sensitive to damage during handling, storage,

and installation. Such damage can degrade cable performance to the extent that replacement

becomes necessary.

Optical fibre Cable is a valuable product. If handling is not done properly, the drum and in

turn the cable may get damaged. At times, the damage might not be discovered until the

installation

process, when repairing the cable gets extremely difficult and also expensive.

There are a number of key safety issues that are important to keep in mind while handling the

Optical fibre Cables as follows:

1. Keep the cable drum/reel protected with outer covering till the time it is used at the

site.

- dr.com has developed an alternative packing plastic

- Drum covered with wooden lags

- Drum left uncovered

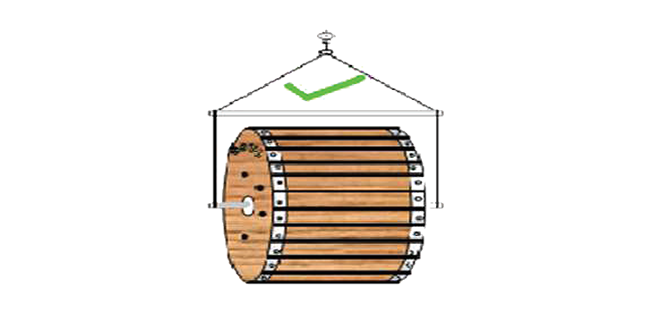

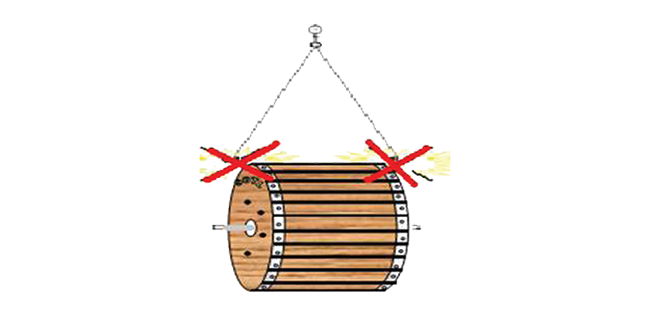

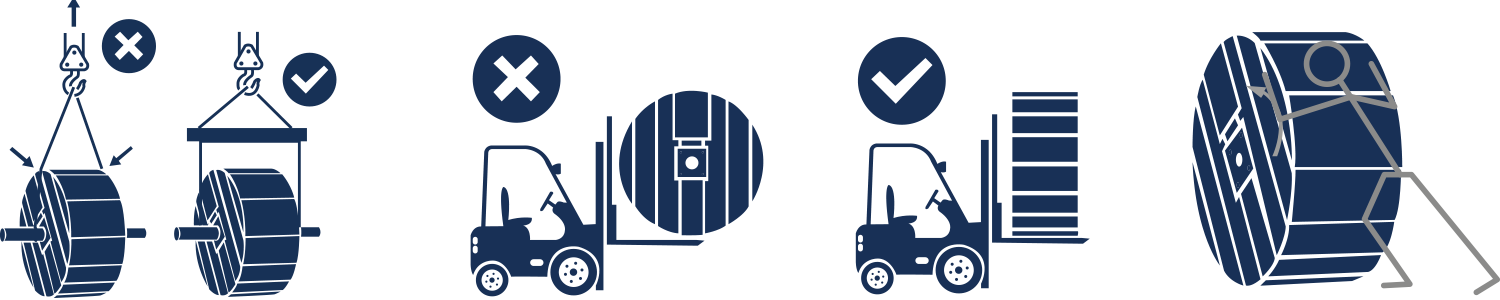

2. Lift the drums without damage

When lifting the drum; use a shaft through the center of the drum and a the spreader beam. In case spreader is not used the rope may damage the flanges of the drum which can cause cable damage.

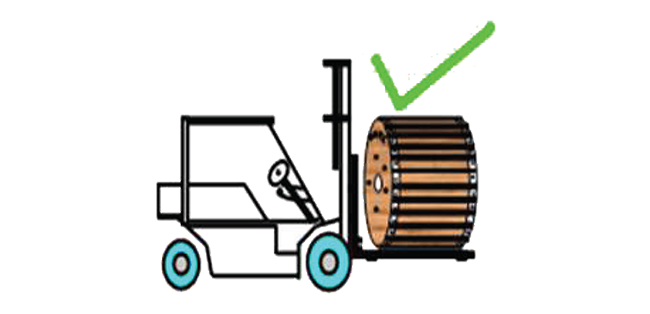

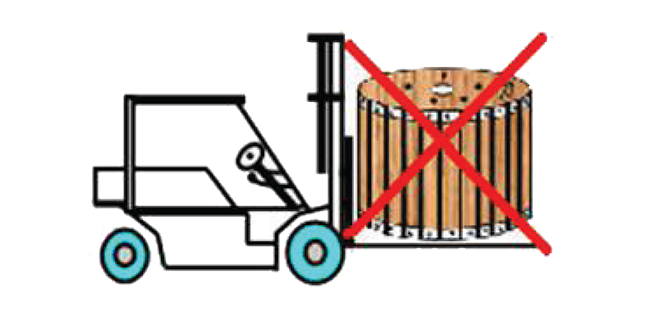

3. Handling with Forklift

Ensure the drums are moved in an upright position and the fork must be longer than the width of the drum. When moving the drums, tilt the truck mast so that the drum remains in the fork and the points don't touch the ground. Raise the forks of the forklift at least 6-8 inches from the ground surface. Don't release the forks until the truck has stopped completely. Keep sufficient space between the drums so that forks don't damage the other drum.

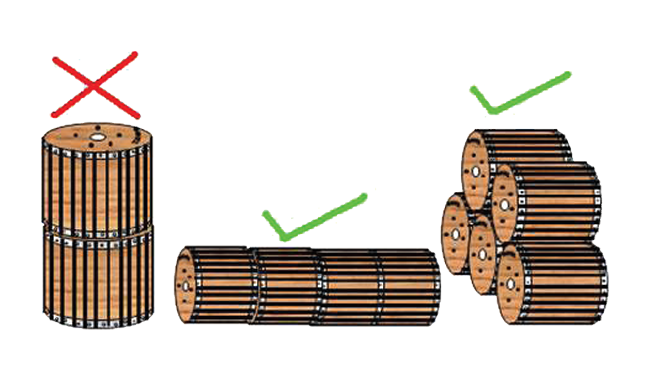

4. Keep the Drum in an upright position

The drum is designed to be handled in an upright position. It may not sustain if lifted laying flat. When stored in an upright position, the cable-layers do not get entangled during uncoiling.

- a) Drum on flange edge

- b) Drum on the Flange Side

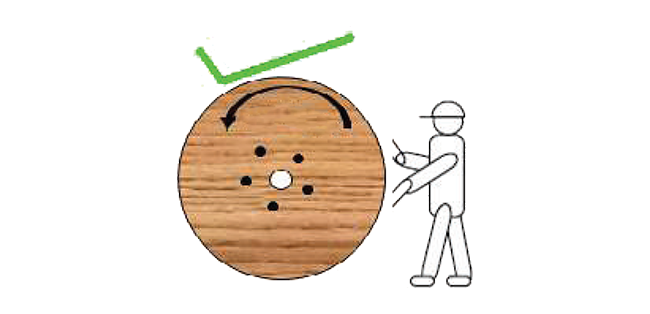

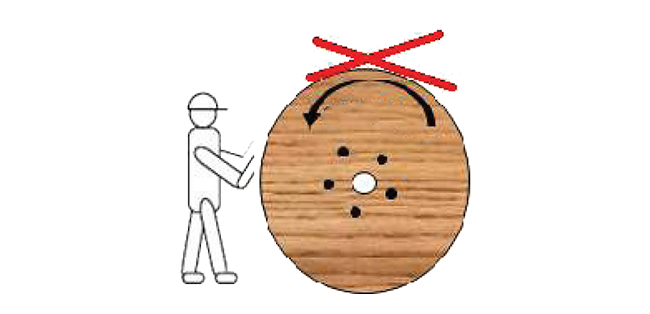

5. Roll the drums only as per the direction marked on the drum flanges

When the drums need to be rolled due to some reason, always roll the drums in the direction of the arrow marked on the drum flanges. This way the cable over the drum will not loosen. However, this does not mean that the drum can be rolled freely for any distance. Limit rolling distance to 5-10 meters. Once placed in position, use a proper stopper to prevent drums from rolling.

- a) Drum on flange edge

- b) Drum on the Flange Side

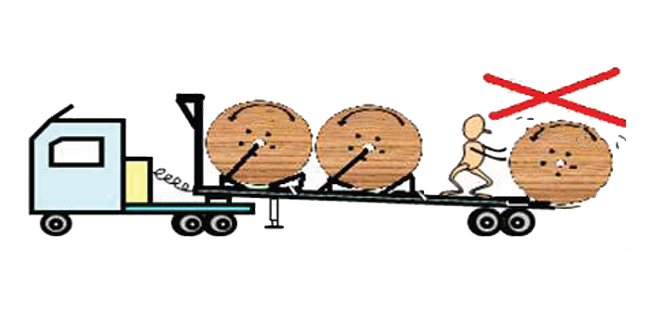

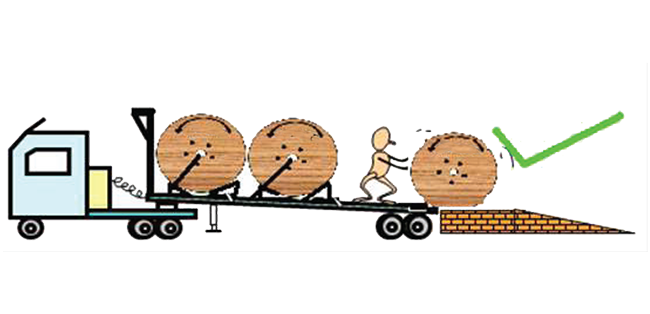

6. Drum transportation, Unloading, and Storage

A) During transportation, the cable drums should not be kept in a Flat position; it crushes down the layer of the cable, resulting in fibre breakage.

B) The cable drums should always be kept in an upright position and be tied with a Chain or Belt with wooden blocks that should be kept in between the flanges of each drum to avoid any jerks/ movements during transportation.

C) While unloading the truck it is important that the cable drum should not be dropped directly on the floor. The weight of the Drum & cable may cause deflection of Drum flange resulting in flattening, deformation, or damage to the cable.

D) The drum must be rolled from a truck on to receiving platform, which should be at the same height as the tailgate of the truck. An alternate is to use a forklift to unload drums from truck.

Note: If inclined ramps are used, roll the drums over it; but don't allow them to roll out of control. Roll each drum away from the bottom of the ramp before handling the next drum.

E) The drums should always be stored in an upright position. Storage of drums in an alternative position can lead to winding defects.

F) If storage place is limited and it becomes necessary to stack, then stack the completely wrapped on their flanges. Stacking is allowed only for the drums whose flange diameter is 1250mm or less. Do not store drums on Flat flanges

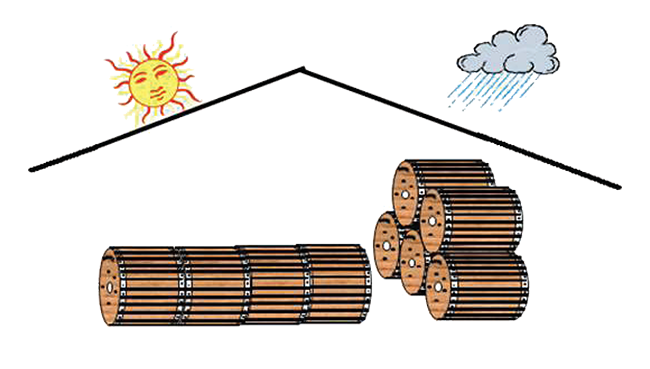

G) Optical fibre cables are winded on wooden drums. Due to the environment surrounding, the drum gets degraded over a period of time. To avoid such degradation in the wood during its storage period, in-house storage is recommended. If drums are stored outside, storing surface should be hard & no moist soil should be in contact with wood, this avoids the generation of harmful insects responsible for wood degradation. During heavy rain, the drums should be closed by polythene to keep the Drum moisture content around 18% to 25%. Copyright

Quality Assurance

As part of our insistence on quality deliveries, we strive

- To improve customer satisfaction

- To improve process efficiency

- To improve employee productivity and motivation

- To improve QMS effectiveness

Measuring the effectiveness of quality initiatives is a prune stimulant for process

improvement. We take a host of measures to ensure that processes are followed religiously

and monitored regularly.

Customer feedback & satisfaction monitoring - Through regular customer interaction and process

and delivery checks.

The "internal efficiency" axis - control of our processes, control of product and service

quality, control of delivery timeframes

Employee satisfaction & knowledge enhancement - Our employees mean a lot to us through constant

motivation and knowledge enhancing training we ensure our employees are happy and not

overloaded or stressed, this in tum helps keep our customers happy and satisfied.

Management Review - Regular internal audits by the management team ensure that our process and

product quality are maintained as per customer requirements.

Standard Method & Procedure for Laying Armoured Cables

Below are some standard methods & procedures for laying armoured cables. This will be the solution for the below problem observed during laying.

1) Method for uncoiling cable from cable reel:

The cable should be uncoiled from the cable reel and shall be arranged in a figure 8 (Eight) shape. The dimensions of each loop of the figure 8 shall be maximum 2 mtrs. This method will avoid cracking of sheath and also avoid damages in the cable while uncoiling cable from the reel. Please refer to the image below for your reference.

2) Minimum Bending parameters

- Cable under no-load condition, Minimum bending radius > 15 X Cable Diameter.

- Cable under load condition, Minimum bending radius > 20 X Cable Diameter.

3) Installation Guidelines as below.

Buried Installation of Optic fibre Cable

A buried cable is a kind of communications cable which is specially designed to be buried under the ground without any kind of extra covering, sheathing, or piping to protect it. This cable is built to specific tolerances to heat, moisture, conductivity, and soil acidity. Unlike standard telecommunications cables, which have only a thin layer of insulation and a waterproof outer cover, Buried Cable may consist of multiple layers of sheathing or jacketing, reinforced by metallic-banded, shock-absorbing gel, wrapped thread-fortified waterproof tape, etc. This Applications Note describes the placement of optical cables as buried cable in the outside plant portion of the communications network.

Introduction

A buried plant is usually placed into a narrow trench or plowed directly in the ground. Sometimes a fibre cable is placed in an open trench with several empty sub-ducts for use when future service demands require more cable infrastructure.

A general description of placing fibre cables will be presented in this Note. The Direct buried cable placing methods described in this document are intended as guidelines. National, state, local, and corporate specifications, regulations, and industry recommendations normally take precedence over these. It is impossible to cover all the conditions that may arise during a placing operation. Individual company practices for placing fibre optic cable should supersede any conflicting instructions in this document whenever they do not exceed the cable's optical and mechanical performance specifications. This note is not intended as a replacement for instructions or operations described by the manufacturer's procedures for the materials and equipment being used.

Advantages of Buried Plant

The construction of a buried plants is popular because it provides three major

advantages over

other types of communications plant construction when used in properly-suited areas.

a. It provides a fast installation procedure.

b. It is economical both in initial investment in infrastructure and it provides good

flexibility

in being able to place the new plant in a more timely manner to closely match new service

demands.

c. It is the least disruptive to surface conditions along the right-of-way.

Buried construction is well suited for use in the following conditions:

- Soils with low clay content.

- Compatible granular soils.

- Free from medium or large-size rocks.

- Free of frozen soil and/or debris.

- Right-of-way with few crossing utilities, roadways, or underground obstacles.

- Right-of-way that crosses open land, free from buildings, and large expanses of paved areas.

Precautions

1) Cable Handling

All-optical cables are sensitive to damage during shipping, handling, and installation. Some of the important parameters that need special attention during cable installation are:

a. Cable Bending radius: Optical fibre cables are designed with a minimum bending

radius

and maximum tensile strength. The cable should never be bent below its minimum bending

radius. Doing so can result in bending losses and/or breaks in the cable's

fibres. Generally

the minimum bending radius of a fibre cable under load is 20 × D, where D is the diameter

of the cable the minimum bending radius of a fibre cable under no load is 15 × D.

b. Cable Placing Tension: Optical cables are designed with maximum tensile

strength. The

cable should never be loaded beyond its maximum tensile strength. Exceeding this value

provided by Sterlite in the Cable Data Sheet / Specification, can alter cable and fibre

performance and shorten its service life.

2) LED and Laser Precaution

LED and Laser beams used in testing fibre optic cable and transmission systems are invisible to the human eye and can seriously damage the eye. Viewing these beams directly may not cause any pain and the iris of the eye does not close automatically as it does while viewing a bright light. As a result, the eye may not react to protect itself, causing serious damage to result to the retina.

3) Material Safety

fibre optic splicing and termination processes often use various chemical cleaners. The safety instructions developed for these substances should be followed. If there is confusion in the usage of these products, ask their manufacturer for a Material Safety Data Sheet (MSDS). Remember the following instructions while working with these chemicals.

1. Always work in well-ventilated areas.

2. Avoid skin contact with these cleaning materials as much as possible.

3. Avoid using chemicals that cause allergic reactions.

4. Isopropyl alcohol, used as a cleaner, is flammable and should be handled carefully.

Note: Warranty for cable will be applicable if the cable is laid as per standard procedure.

CATV OPTICAL FIBRE CABLES

Handling & Installtion Guidelines

- When lifting with a crane drums should be properly supported with a through shaft and spreader bar to prevent damage to the drum.

- When using a forklift truck to lift the cable, the drum must be handled correctly, lifting from the right direction.

- Wooden drums frequently have an arrow marked on their flanges to indicate which side drum should be rolled.

Installation Technique :

- Provide adequate extra length of cable at the pole for testing and jointing.

- Consider cable weight, thermal changes, wind/ice loading, etc to avoid strain on fibre.

- Ensure clearance between Fibre optic cables and other utility cable/wire.

- Cable containing steel wire strength members should be electrically grounded.

- Never exceed the cable’s rated pulling strength.

- Cable should be install along with external messenger wire.

- Cable should be clamped to the support messenger wire at 3-5 meter intervals, providing 2 to 3% Sag. This will give long life for the cables & save replacement cost.

- The design Span Length is 20 meters.

- Take OTDR mesurement before and after installation.